Light Guides shown without cover masks.

New Technology

Nano-Imprinted Thin Films create unique LED Backlighting for the full range of Electronics Equipment applications.

High Resolution patterns

Micro-Lenses are Nano-Imprinted onto Thin, Flexible Translucent Substrates.

Nano-structured Light Control

Uniquely allows for sophisticated control of light distribution only to keys or buttons dramatically increasing efficiency and brightness.

Roll to Roll, High Efficiency Production

Provides Very Cost-Effective and High Quality, High Repeatability products.

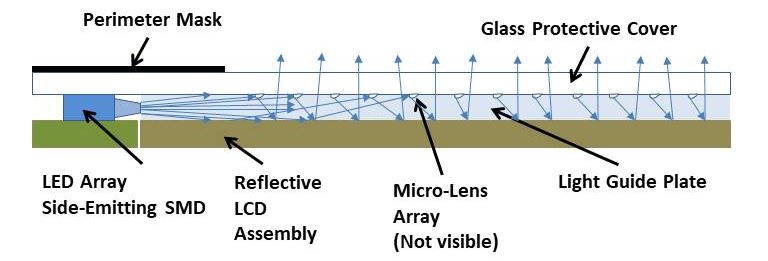

Light Guide Films: How they work.

The Light Guides are designed for effective use of LED edge light sources. Light from the LED sources is internally reflected down the length of Light Guide to the various viewing areas. The Localized Micro-Lens Arrays redirect light out of the film to the viewer only where it is needed (to each logo, image, key or button) by layout design. This new technology patterning allows light to be efficiently and uniformly directed where light is desired in a very low profile film.

Light Guide Film Benefits

- Very efficient use of light only to areas to be illuminated. Patterns of MicroLense areas designed by Customer software such as CAD or other standard design software.

- More Efficient use (and reduced numbers) of LED sources

- Very Thin Form Factor.

- Roll to Roll Film Manufacturing for Low Cost

- Software Designed Patterns for Precise Light Control.

- Die cut to your specification shape.

Light Guide Assemblies are an Option....

There are several options that can allow you to have custom components which are bonded together into one assembly for easy installation into your product design….

- Front Glass or Plastic Cover which may include specialty coatings.

- Back Light Guide layer

- Backside Reflector

- LED Assembly including flex circuit for mounting LEDs and connection to your PCB.

- Touch activations

- Interlayer Adhesives to complete the assembly

Design

Light guides are designed using customer CAD or other software to determine the size, pattern and layout of the microlens arrays. This input is combined with our software to create the Micro-Lens array that is imprinted onto the Light Guide.

Specifications

| Materials | Optical Grade Materials | Polycarbonate, Acrylic (PMMA) | |

| Thickness | Ultra Slim Profile | 0.40 mm to 0.8 mm | |

| Max. Size | Standard..Inquire for larger | 300mm x 400mm (11.8″ x 15.7 “) | |

| Options | Various design added options | LEDs, Cover Plates, Protective Films, Adhesives | |

| Technology | High Resolution Nano imprinting | Less than 50 micron diameter lens structures are not visible. | |

| Applications | Low Power Portable Devices | Notebooks, PC’s, Game Sets, Small Handhelds, Custom Displays, etc |