Very Uniform Light Sources

Applications

- Uniform Light Sources are useful for a wide range of applications including medical, scientific, machine vision and photography.

- They offer lower power consumption compared to traditional LED arrays.

- Front lighting offers a see through light source that can provide more direct lighting without any shadows.

- Back lighting can provide very clean, crisp lighting for silhouettes image monitoring.

- Works well with all LED light colors and brightness.

Benefits

- Low Power Consumption…as much as 90% less depending on the application.

- Uniformity better than 85%

- Transmission better than 85%

- Brighter with Fewer LEDs

- Ultra-Thin Profile

- Lower Cost

- Flexible (within limits of selectied materials.)

- Custom Design available with size, shape, LED arrays, reflectors, coatings and other options available.

Technical Advantages

- High uniformity improved by our unique ability to vary Micro-lens density over the surface to control light distribution.

- Micro-lens technology provides brighter transfer of light to the viewer.

- Use of Light Guide Plate compared to Injection Molded Plates reduces profile with improved performance.

- Roll to Roll imprint manufacturing offers a lower cost alternative to molded plastic light guides.

- Customized sizes, thicknesses and shapes are accommodated within capabilities.

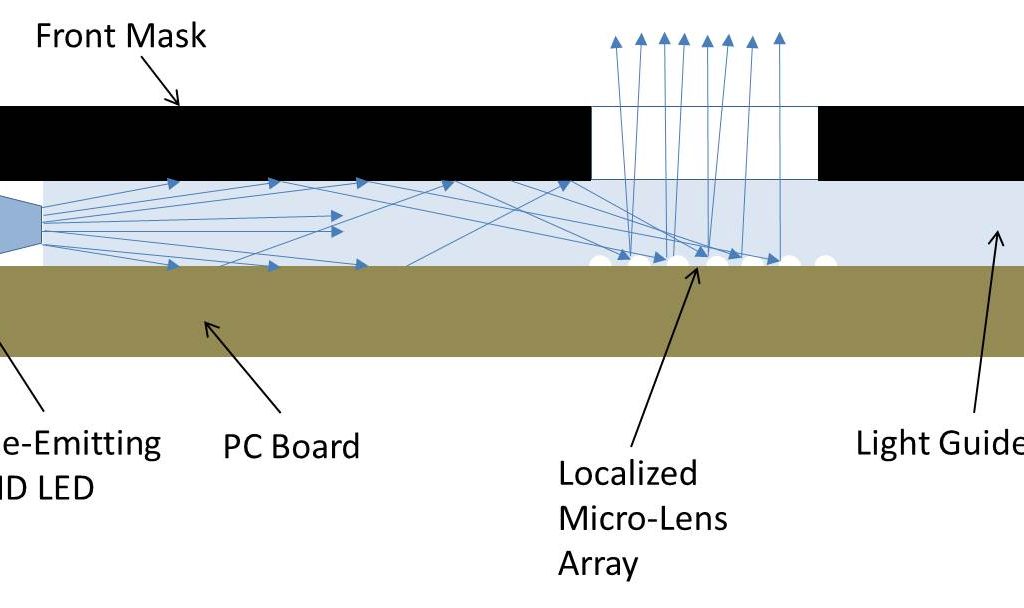

Light Guide Plates: How they work

The Light Guide Films (LGFs) and Plates (LGPs) are designed for effective use of LED edge light sources. Light from the LED sources is internally reflected down the length of LGF or LGP to the various viewing areas. The Localized Micro-Lens Arrays redirect light out of the film to the viewer only where it is needed (to each logo, image, key or button) by layout design. This new technology patterning allows light to be efficiently and uniformly directed where light is desired in a very low profile film.

Light Guide Assemblies are an Option....

There are several options that can allow you to have custom components which are bonded together into one assembly for easy installation into your product design….

- Front Glass or Plastic Cover which may include specialty coatings.

- Back Light Guide layer

- Backside Reflector

- LED Assembly including flex circuit for mounting LEDs and connection to your PCB.

- Touch activations

- Interlayer Adhesives to complete the assembly

Light Guide Plate Specifications

| Materials | Optical Grade Materials | Polycarbonate, Acrylic (PMMA) | |

| Thickness | Ultra Slim Profile | 0.40 mm to 0.8 mm | |

| Size Range | Standard…..Inquire for larger | 2mm (1″) to 300mm x 400mm (11.8″ x 15.7 “) | |

| Options | Various design added options | LEDs, Flex Circuits, Cover Plates, Protective Films, Coatings, and Adhesives | |

| Technology | High Resolution Nano imprinting | Less than 50 micron diameter lens structures are not visible. | |

| Applications | Control button, Keypads Logos, and Decor Lighting. | Control Panels of all Types including portables. High quality Logo Lighting. |